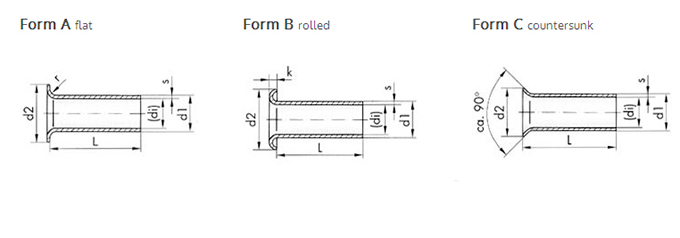

Tubular rivets are manufactured according to GB-975/DIN 7340 with flat head (Form A), roller-performed round head (Form B) or with countersunk head (Form C) from seamless, drawn precision tubes. This offers the advantage over deep-drawn hollow rivets, that both the internal and external diameters of the shaft are accurately cylindrical and thus there is a constant wall thickness. In addition to DIN 7340 we manufacture tubular rivets with all intermediate dimensions; the customer can specify the head form, external diameter, wall thickness, length and surface finish according to his requirements. Special dimensions can be produced according to drawings or supplied samples.

| Material | Name | d1 | s | L | Head form | Finish |

| brass | tubular rivet | 5 | 0,5 | 20 | A | clean |

| brass tubular rivet A 5 x 0,5 x 20 mm, DIN 7340, clean | ||||||

| copper | tubular rivet | 2 | 0,2 | 3 | B | silver plated 5 µm |

| copper tubular rivet B 2 x 0,2 x 3 mm, DIN 7340, silver plated 5 µm | ||||||

If nothing else has been prearranged we produce according the tolerances below:

| tube-Ø | d1 | 1 | 1,2 | 1,5 | 2 | 2,5 | 3 | 4 | ||||||||

| Tol. | ±0,03 | ±0,03 | ±0,03 | ±0,03 | ±0,05 | ±0,05 | ±0,07 | |||||||||

| wall thickness |

s ± 10% |

0,2 | 0,2 | 0,2 | 0,25 | 0,2 | 0,3 | 0,25 | 0,3 | 0,4 | 0,25 | 0,3 | 0,5 | 0,3 | 0,4 | 0,5 |

|

(result. internal Ø) |

di | 0,6 | 0,8 | 1,1 | 1 | 1,6 | 1,4 | 2 | 1,9 | 1,7 | 2,5 | 2,4 | 2 | 3,4 | 3,2 | 3 |

| Tol. | ±0,07 | ±0,07 | ±0,07 | ±0,08 | ±0,07 | ±0,09 | ±0,1 | ±0,11 | ±0,13 | ±0,1 | ±0,11 | ±0,15 | ±0,13 | ±0,15 | ±0,17 | |

| head-Ø | d2 | 1,6 | 2 | 2,5 | 3,2 | 4 | 4,5 | 6 | ||||||||

| Tol. | ±0,15 | ±0,15 | ±0,15 | ±0,2 | ±0,2 | ±0,2 | ±0,25 | |||||||||

| k approx. | 0,25 | 0,3 | 0,35 | 0,4 | 0,4 | 0,45 | 0,4 | 0,5 | 0,6 | 0,5 | 0,5 | 0,6 | 0,65 | 0,7 | 0,8 | |

| r max. | 0,2 | 0,25 | 0,3 | 0,4 | ||||||||||||

| tube-Ø | d1 | 5 | 6 | 8 | 10 | ||||||||||

| Tol. | ±0,07 | ±0,1 | ±0,1 | ±0,01 | |||||||||||

| wall thickness |

s ± 10% |

0,3 | 0,5 | 0,75 | 0,4 | 0,5 | 0,75 | 1 | 0,4 | 0,5 | 0,75 | 1 | 0,5 | 0,75 | 1 |

| (result. internal Ø)) | di | 4,4 | 4 | 3,5 | 5,2 | 5 | 4,5 | 4 | 7,2 | 7 | 6,5 | 6 | 9 | 8,5 | 8 |

| Tol. | ±0,13 | ±0,17 | ±0,22 | ±0,18 | ±0,2 | ±0,25 | ±0,3 | ±0,18 | ±0,2 | ±0,25 | ±0,3 | ±0,2 | ±0,25 | ±0,3 | |

| head-Ø | d2 | 7,5 | 9 | 12 | 15 | ||||||||||

| Tol. | ±0,25 | ±0,25 | ±0,3 | ±0,3 | |||||||||||

| k approx. | 0,75 | 0,9 | 1 | 0,95 | 1 | 1,1 | 1,3 | 1,2 | 1,3 | 1,4 | 1,5 | 1,5 | 1,6 | 1,7 | |

| r max. | 0,5 | 0,6 | 0,8 | 1 | |||||||||||

| Length L | 2-3 | 3,1-6 | 6,1-10 | 10,1-18 | 18,1-30 | 30,1-50 | 50,1-60 |

| Tolerance | ±0,12 | ±0,15 | ±0,18 | ±0,2 | ±0,25 | ±0,3 | ±0,35 |

| Standard materials | |

| Brass (Ms) | Aluminium (Al) |

| Copper (Cu) | Stainless steel (Est) |

| Steel (St) | |

Online Consultation

Working Day:9:30-21:00

Weekend:10:00-17:00

Online Consultation